Thermo Mechanically Treated (TMT) bars are one of the most essential construction materials used in modern civil engineering projects. Known for their high tensile strength, flexibility, and resistance to corrosion, TMT bars provide the necessary reinforcement for concrete structures such as buildings, bridges, dams, and highways. The manufacturing process involves controlled quenching and tempering, which gives the outer layer a tough surface while keeping the core ductile. This combination ensures durability, seismic resistance, and enhanced bonding with concrete. TMT bars are available in different grades and diameters, making them suitable for both residential and large-scale infrastructure projects.

Hot‑rolled (HR) coils & sheets are steel sheets made by rolling steel while it’s glowing hot. This makes them easy to shape and bend. They cost less than cold‑rolled steel, have good strength and weld easily. These sheets and coils are useful in construction, heavy machines, and parts where a smooth surface or exact size isn’t very important.

Cold‑rolled (CR) coils & sheets are steel products made by first hot rolling and then further processing the steel at room temperature. This extra step gives a smooth, clean surface; exact thickness; and tighter size control. They are stronger and more precise than hot‑rolled steel, with better ability for fine shaping, welding, dent resistance and good finish for paint. Industries like automobiles, home appliances, furniture, electrical panels, precision engineering and construction use CR coils/sheets where the look, fit, and finish matter.

Dowel bars and round bars play a critical role in civil construction and mechanical engineering applications. Dowel bars are short steel bars used to provide a mechanical connection between slabs without restricting horizontal joint movement, making them vital for road pavements, airport runways, and industrial flooring. Round bars, available in mild steel and alloy grades, are versatile products used for shafts, fasteners, machine parts, and decorative architectural elements. Their uniform cross-section and strength make them highly dependable in both construction and manufacturing. Together, dowel and round bars ensure structural stability, load transfer efficiency, and long-term durability in infrastructure and engineering works.

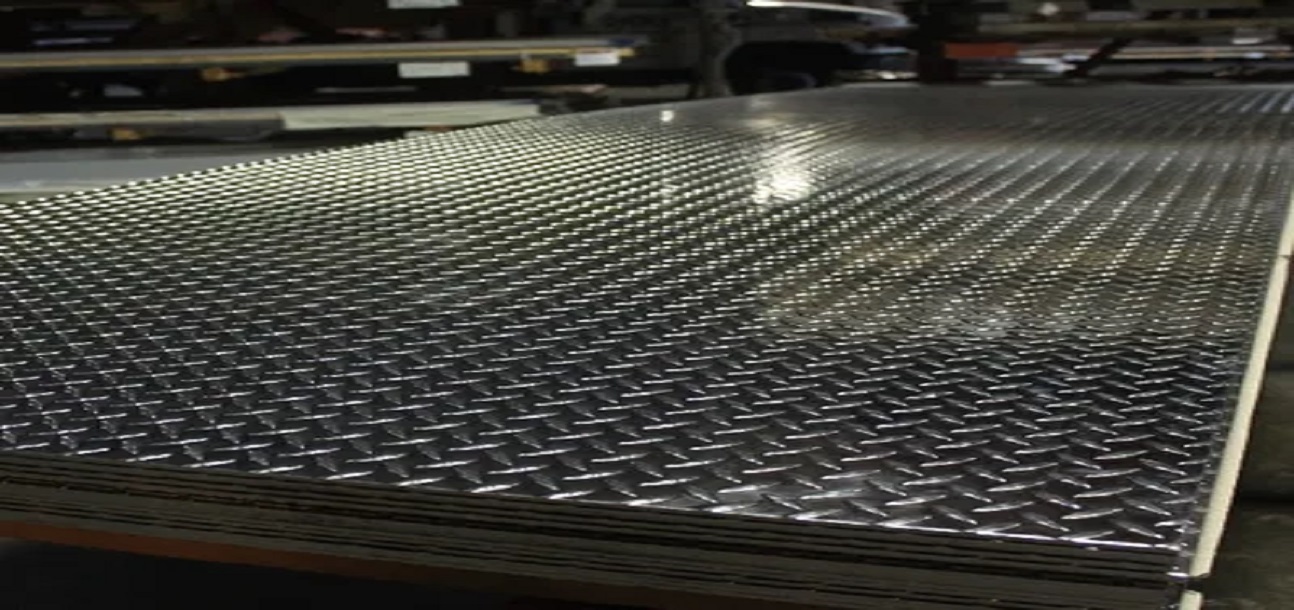

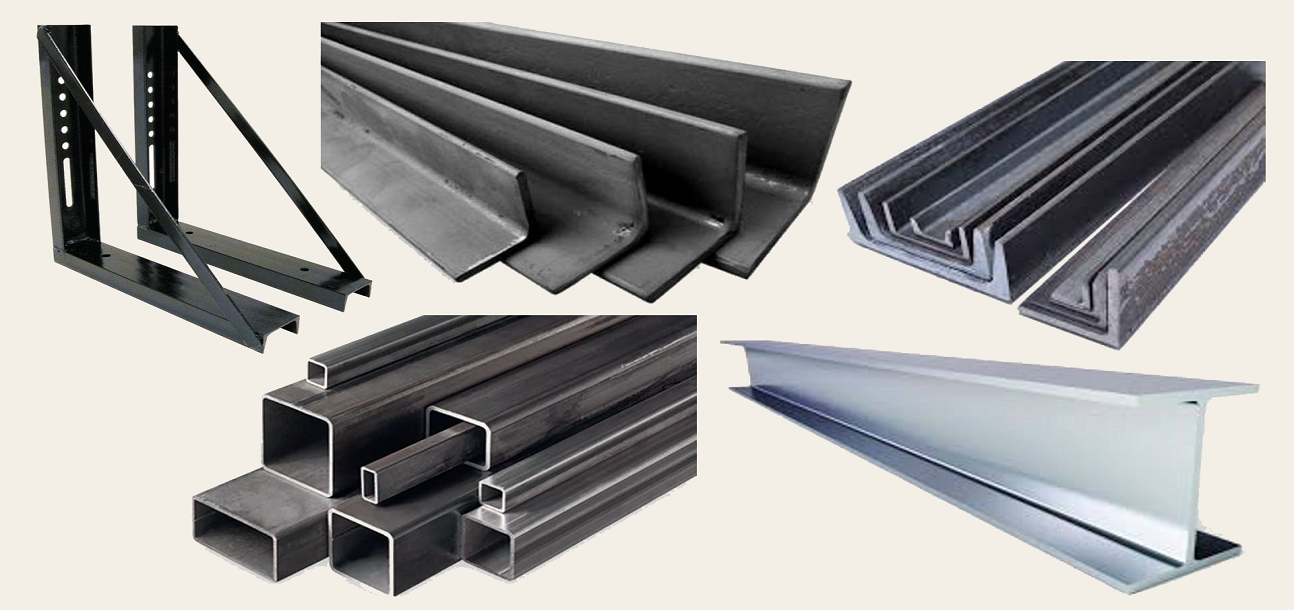

Structural steel refers to a category of steel specifically designed to be used in construction frameworks and heavy-duty applications. It comes in various shapes such as angles, beams, channels, tees, and hollow sections, all of which provide different load-bearing properties. Known for its strength-to-weight ratio, structural steel offers exceptional durability while allowing flexibility in design, making it ideal for high-rise buildings, bridges, industrial sheds, warehouses, and large infrastructure projects. Its recyclability and cost-effectiveness further add to its value. Structural steels are engineered to withstand heavy loads, seismic forces, and harsh weather conditions, ensuring long-lasting and reliable construction.

These structural elements are engineered to provide maximum strength while occupying minimal space, perfectly suited for the demands of modern construction and architectural design.

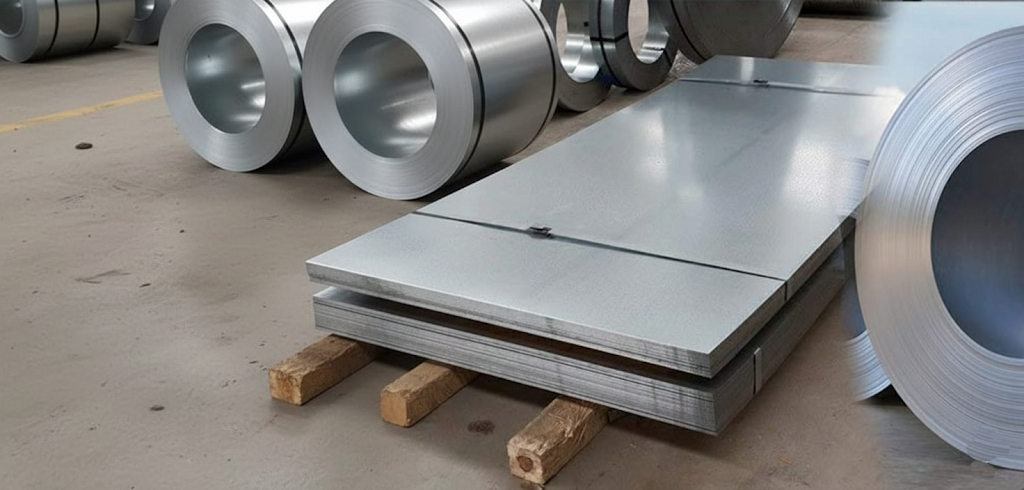

Galvanized Plain (GP) coils and sheets are made by coating steel with a protective layer of zinc through a continuous hot-dip process. This zinc coating provides excellent resistance to rust and corrosion, making GP steel suitable for a wide range of applications. GP sheets are widely used in ducting, automobile bodies, household appliances, electrical panels, and furniture, while GP coils are favored by manufacturers for fabricating customized products. Their uniform surface finish, formability, and durability ensure reliability in both indoor and outdoor uses. GP coils and sheets combine strength, longevity, and cost-efficiency, making them a staple in the steel industry.

DI Pipe (Ductile Iron Pipe) is a robust and durable pipe made from ductile cast iron, which combines the strength of steel with the corrosion resistance of cast iron. It is widely used for water supply, sewage, and industrial piping systems because of its ability to withstand high pressure and harsh conditions. DI pipes are internally lined (often with cement mortar) to prevent corrosion and ensure long service life, while externally coated for added protection. They are available in various sizes and pressure classes, making them suitable for both underground and above-ground applications in municipal, industrial, and utility networks.